kfweili@gmail.com +86 158 3786 7107

Jan 08 , 2019

Differential pressure transmitter installation position selection:

1. Corrosive or overheated media should not be in contact with the differential pressure transmitter.

2. Prevent the slag from being precipitated in the pressure tube.

3. The hydraulic heads in the two pressure piping should be balanced.

4. The pressure piping should be as short as possible.

5. The pressure piping should be installed where the temperature gradient and temperature fluctuations are small.

6. Measuring liquid circulation: The pressure faucet ought to be opened on the side of the process pipe to avoid sedimentation. The differential pressure transmitter should be set under the side or under the pressure port to permit gas to drain in the process piping.

7. Quantify the gas flow rate: The strain faucet ought to be discharged at the top or side of the process pipe, and the differential pressure transmitter should be installed beneath the pressure tap to permit liquid to drain into the process pipe.

8. Measure the vapor flow rate: The pressure vent should be opened on top or side of the process pipe, and the transmitter should be installed beneath the pressure port to allow the condensate to flow into the pressure tube.

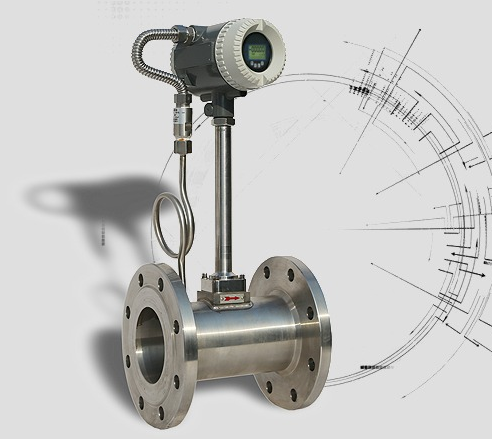

We are Ultrasonic Heat Meter Supplier, providing you with quality products and services that make our mission.

If you need a Mechanical Flow Meter, please do not hesitate to contact us.